Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Calculation and Selection of Differential Pressure Controller

Calculation Methodology

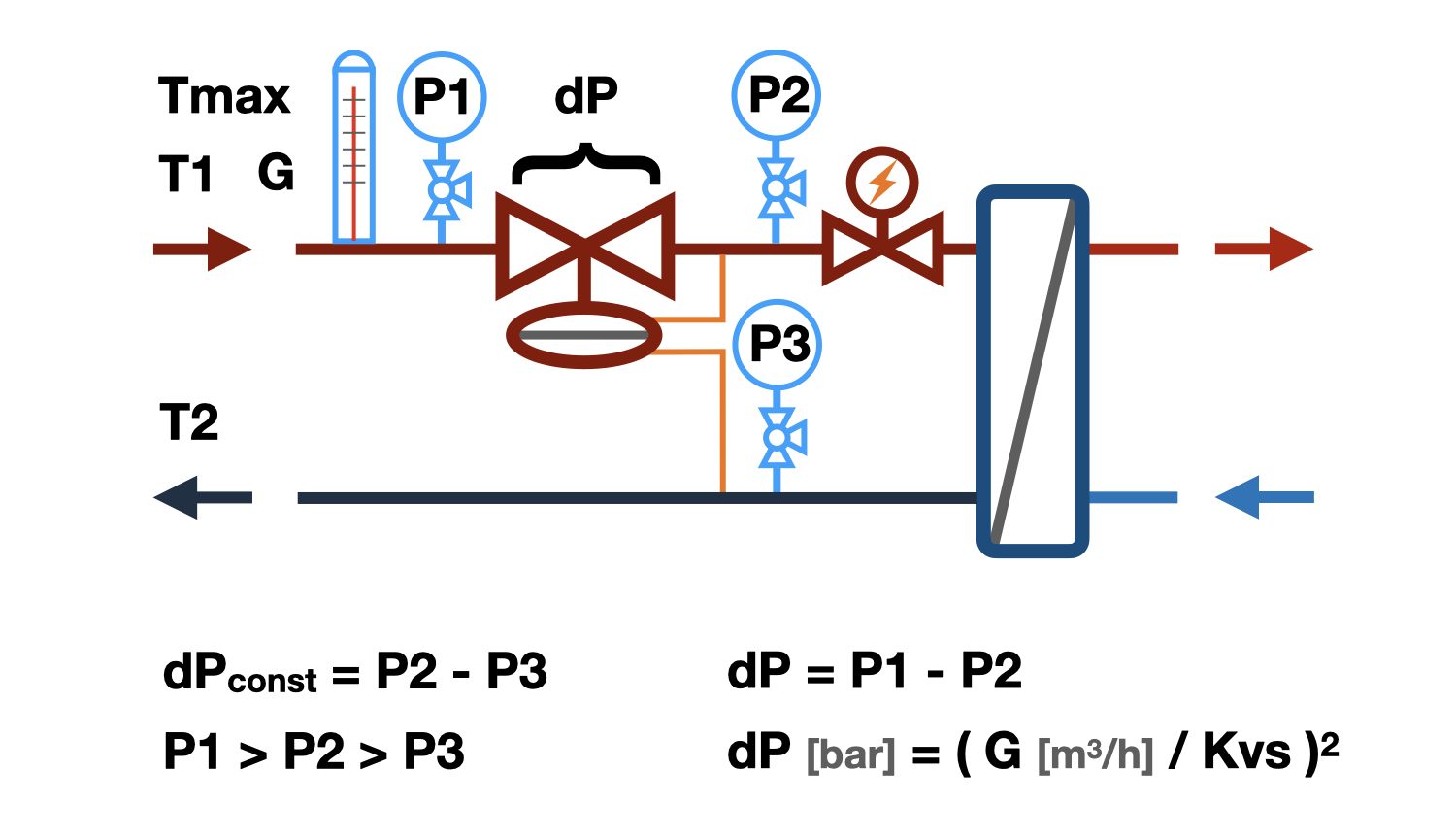

Calculating the differential pressure controller involves determining flow capacity, required adjustment range, and checking for potential noise and cavitation.

Kvs Flow Capacity Calculation

The dependence of pressure loss on water flow through the differential pressure controller is called flow capacity - Kvs.

Kvs - flow capacity, numerically equal to the water flow in m³/h through a fully open differential controller gate, at which the pressure drop equals 1 bar.

Kv – the same at partial gate opening of the controller.

Knowing that when the water flow changes by 'n' times, the pressure loss on the controller changes by 'n²' times, it's easy to determine the required Kv value of the differential pressure controller by substituting the calculated flow rate and excess pressure into the equation.

Some manufacturers recommend choosing a differential pressure controller with the nearest larger Kvs value than the calculated Kv value. This selection approach allows more precise water flow regulation below the set value, but does not allow flow increase. We recommend selecting differential pressure controllers so that the required flow capacity falls within 40 to 70% of the stem stroke range. A differential pressure controller selected this way can reduce water flow with sufficient accuracy and also slightly increase it.

The selection result shows the percentage of the differential pressure controller gate opening at which the specified excess pressure is throttled at the given water flow rate.

Adjustment Range Selection

The adjustment range of the differential pressure controller depends on the spring compression force. Some differential controllers come with a single spring and have only one adjustment range, while others may be equipped with springs of varying stiffness and have multiple adjustment ranges. The differential pressure to be maintained by the controller should fall within the middle third of the adjustment range.

The above selection algorithm generates a list of controllers for which the specified differential falls within 20 to 80% of the range of supported differential pressures.

Cavitation Check Calculation

Cavitation is the formation of vapor bubbles in the water flow, occurring when the pressure drops below the water vapor saturation pressure. The effect of increased flow velocity and pressure drop, which occurs at the narrowing of the passage, is described by Bernoulli's equation. The passage in the differential pressure controller is precisely this narrowing where pressure may fall to saturation level, making it the most likely place for cavitation to occur. Vapor bubbles are unstable; they suddenly appear and then disappear just as quickly, leading to the erosion of metal particles from the controller's elements, which will inevitably cause its premature wear. In addition to wear, cavitation leads to increased noise during controller operation.

Main factors influencing cavitation occurrence:

- Water temperature - the higher it is, the more likely cavitation will occur.

- Water pressure - before the differential controller, the higher it is, the less likely cavitation will occur.

- Throttled pressure - the higher it is, the more likely cavitation will occur.

- Cavitation characteristics of the controller - determined by the features of the controller's throttling element. The cavitation coefficient varies among different types of controllers and should be indicated in their technical specifications, but since most manufacturers do not specify this value, the calculation algorithm includes a range of the most likely cavitation coefficients.

After cavitation check, the following results are possible:

- “No” - cavitation will definitely not occur.

- “Possible” - cavitation may occur in some valve designs, it is recommended to change one of the factors mentioned above.

- “Yes” - cavitation will definitely occur, change one of the factors influencing cavitation occurrence.

Noise Check Calculation

High flow speed in the inlet pipe of the controller may cause a high noise level. For most rooms where differential pressure controllers are installed, the allowable noise level is 35-40 dB(A), which corresponds to an inlet pipe speed of approximately 3 m/s. Therefore, when selecting a differential pressure controller, it is recommended not to exceed the above speed.

question : comment : feedback

Online Equipment calculations

Online Equipment calculations

EXAMPLE

EXAMPLE