Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

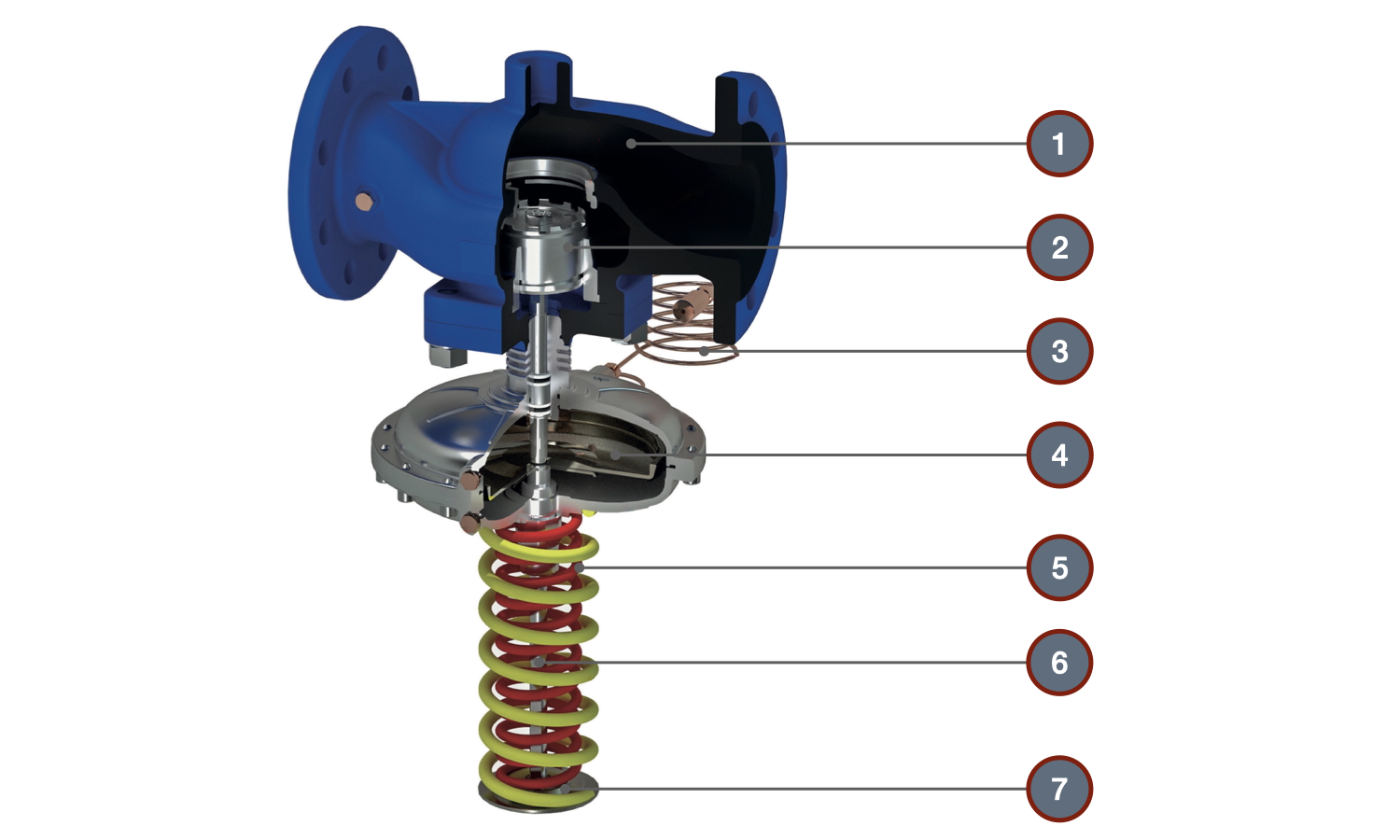

Design of the differential pressure controller

- 1 - Seat valve

- 2 - Valve disc

- 3 - Impulse line

- 4 - Flexible diaphragm

- 5 - Spring setpoint adjuster

- 6 - Steel moving stem

- 7 - Adjustment nut

Design of the differential pressure controller can be of two fundamentally different types: direct-acting and indirect-acting controllers.

Indirect-acting differential pressure controllers use an external energy source to change the valve passage area. The measuring element consists of two pressure sensors that send signals to a controller, which then generates a control signal for the regulating valve. Due to the complex design and high cost, indirect-acting controllers are rarely used despite their high accuracy in maintaining pressure difference. These controllers can be assembled using any regulating valve, almost any pressure sensor, and a controller.

A direct-acting differential pressure controller has a measuring element that acts on the regulating component without additional energy sources, using the working medium's energy. These are proportional controllers where valve opening corresponds to the deviation of the regulated parameter, and the opening speed matches the rate of pressure difference change.

The design of a direct-acting differential pressure controller necessarily includes a setpoint, two impulse lines, measuring and regulating elements. Depending on the type, the measuring element can be a diaphragm, bellows, or piston, while the setpoint device can be a spring, pneumatic, or lever-weight mechanism. The impulse line may be integrated into the valve body or connected to the pipeline through an impulse tube.

The valve of a differential pressure controller may be pressure-balanced or unbalanced, single- or double-seated, and can be connected to the pipeline with threaded, flanged, or welded connections.

Among the many designs, differential pressure controllers for water typically use a single-seated valve, a spring setpoint, and a diaphragm measuring element. These devices, known as diaphragm controllers, maintain pressure difference with high accuracy, are reliable in operation, and repairable, though slightly more expensive than spring controllers.

Spring differential pressure controllers are devices with a single-seated valve, spring setpoint, and the valve shutter as the measuring element. The cost of a spring controller is lower than that of an equivalent diaphragm controller, with a simpler design but lower pressure-maintenance accuracy.

Spring counterparts to diaphragm differential pressure controllers that open with an increase in pressure difference above the setpoint include only certain types of bypass valves. For diaphragm controllers that close with an increase in pressure difference above the setpoint, no spring equivalents exist.

question : comment : feedback

258

Catalog of

Catalog of differential pressure controllers

Danfoss

Danfoss

Danfoss

Danfoss

Danfoss

Danfoss

LDM

LDM

LDM

Herz

Herz

IMI Hydronic

IMI Hydronic

IMI Hydronic

IMI Hydronic

Oventrop

Oventrop

КПСР Групп

Samson

Samson

Samson

Samson

Clorius

Clorius

IMI Hydronic

IMI Hydronic

Broen

Broen

Samson

Samson

Tutorial Herz

Tutorial Herz