Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Calculation of Solid Fuel Boiler

Selection of a solid fuel boiler

When selecting a solid fuel boiler, the following factors should be taken into account:

1 The thermal power of the boiler (the amount of heat produced by the boiler per hour) can vary significantly depending on the type of fuel used and the combustion phase.

2 The nominal thermal power of the boiler stated by the manufacturer in the technical specifications is achieved when burning anthracite coal, which has the highest combustion heat. Therefore, when calculating the power of a solid fuel boiler, enhancement coefficients are used for other types of fuel:

- 1.05 for bituminous coal

- 1.18 for brown coal

- 1.25 for peat briquettes

- 1.25 for dry wood with 15-20% moisture content (two years of drying)

- 3.33 for fresh wood with 70-80% moisture content

3 Manufacturers determine the nominal thermal power of the boiler as the average hourly power produced by the boiler during the combustion of one full load of anthracite coal, during which the combustion process proceeds in normal mode with an excess of oxygen.

Usually, the time of burning one load in such a mode is no more than 4 hours. This means that during the first and last hours of combustion, the boiler can produce 70% of the nominal power, and during two hours of active combustion phase, it can operate with a power of 130%. The nominal power in the technical specifications of the boiler is indicated by the average 100%=(70 +130 +130 +70)/4.

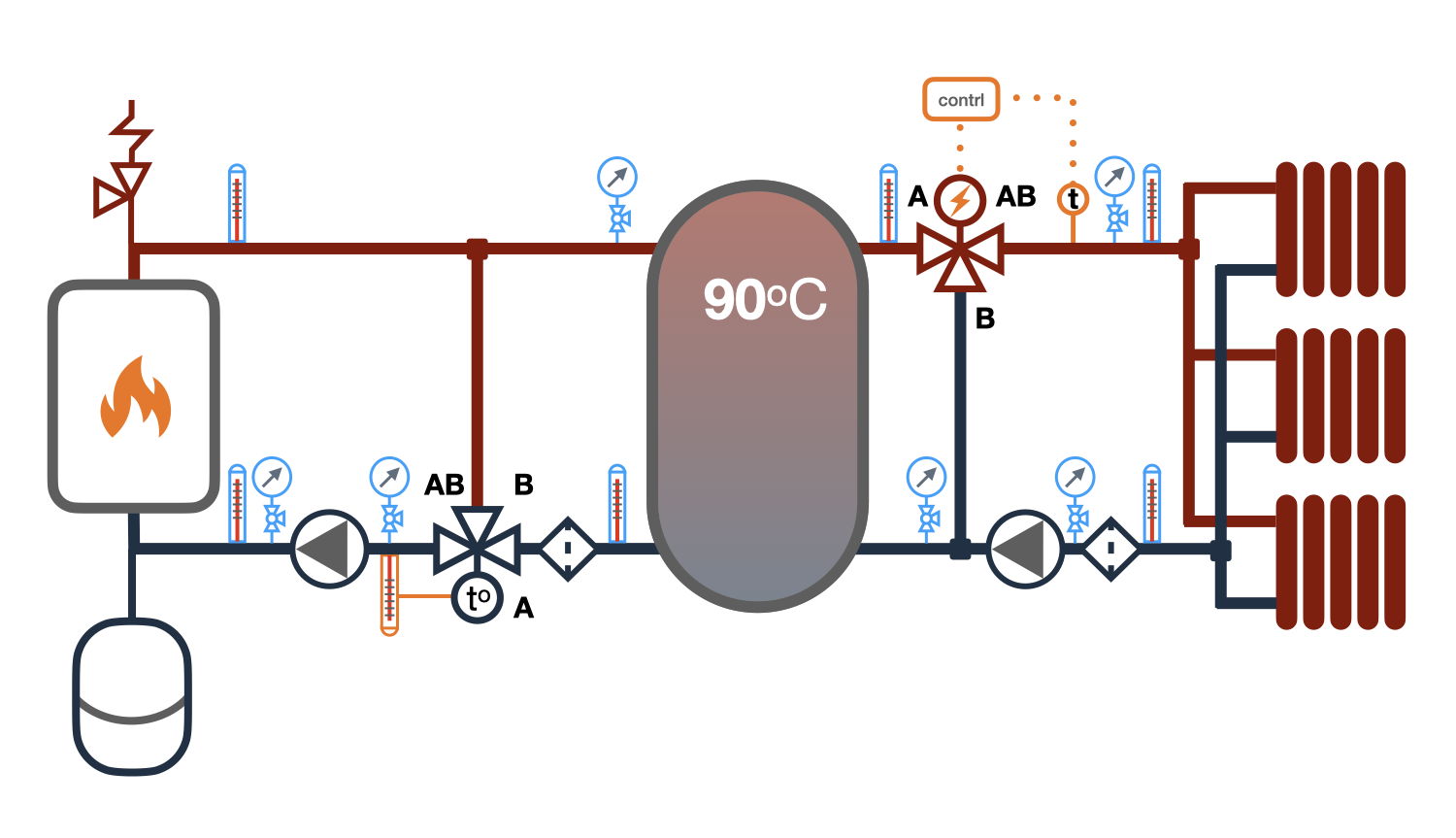

It is very important to take this feature into account when calculating a solid fuel boiler and choosing a connection scheme.

4 When choosing a solid fuel boiler, it is recommended to provide a reserve of power relative to the power of the heat consumption system of about 25-30%. The boiler power reserve will allow:

- to cover unaccounted for heat losses in the calculation

- to compensate for the discrepancy between the quality of the fuel and the declared values

- іncreasing the burning time of a single fuel load, since higher power boilers usually have larger loading chambers.

- еo cover the power required for heating hot water, if the boiler is selected under the load of the heating system.

To take into account the above factors when calculating a solid fuel boiler, designers often use double power increases, although the reserve leads to excessive costs for its purchase.

5 Regardless of what the boiler manufacturers write in the specifications, if it is not pyrolytic, it will not burn for more than 12 hours. In order for a solid fuel boiler to burn for 12 hours, it must burn in a smoldering mode with a deficit of oxygen in the combustion chamber, which significantly increases the ash content and reduces the efficiency of fuel combustion. The mode of long-term burning with a lack of oxygen is not recommended by any manufacturer, but rather used simply as an advertising ploy.

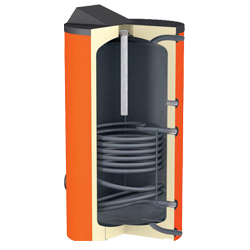

Therefore, if a load on the boiler every 4-6 hours is unacceptable to you, it is better to prefer pyrolytic boilers or use a connection scheme with a heat accumulator.

6 Some types of fuel burn quickly, others - slowly. This feature should also be taken into account when calculating a solid fuel boiler if the frequency of fuel loading is an important factor for you. The online calculation given above will determine the amount of thermal energy produced from one fuel load in kW * h and the duration of its burning.

Features of choosing a solid fuel boiler for a heating system

When choosing a heating boiler, it should be taken into account that the calculated thermal power of the heating system is required no more than 5-7 days of the heating period.

The thermal power of the heating system is calculated for the temperature of the coldest five-day period, eight of the coldest winters in the last 50 years.

The average hourly heat consumption by the heating system during the heating period is approximately half of the calculated heat load of the heating system. Therefore, if a solid fuel boiler is selected with a recommended power reserve of 30% for the calculated outside air temperature, i.e. 130% of the required power at the calculated temperature, then during the average load of winter, its power reserve will be 260% of the required power.

From this, it follows that the warmer it is outside, the longer one full fuel load will burn.

question : comment : feedback

Online Equipment calculations

Online Equipment calculations

EXAMPLE

EXAMPLE