Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Calculation of Safety Valve

Calculation of a safety valve

Calculation of a safety valve is performed using the algorithm for calculating safety valves for boilers with artificial circulation in accordance with SNiP II-35 'Boiler plants'.

In the calculation, the stroke lift height equal to 1/20 of the seat diameter is adopted, since most manufacturers do not indicate the actual stroke lift height in the technical specifications. Therefore, the type size of the safety valve obtained as a result of the calculation may be slightly overestimated. In any case, after selecting the valve, compare the thermal power of your system with the manufacturer's recommended maximum power for this type size, as stated in the technical description.

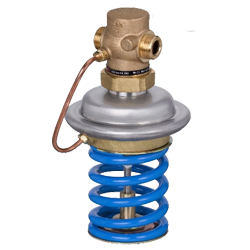

The safety valve is designed to protect systems from exceeding the maximum allowable pressure. The calculation of the safety valve should essentially be reduced to determining the most probable sources of pressure increase and calculating the maximum volume increase of water in the system.

The sources of volume increase may include:

- Overheating of water in the boiler or heat exchanger with subsequent steam generation. At the moment of steam generation, water increases its volume by 461 times, so the steam generation factor is predominant when choosing a safety valve, and it is precisely this factor that is taken into account by the calculation methodology presented in SNiP II-35.

- Failure of the control automation of the feed line for boilers and independent heating systems may become the predominant factor in pressure systems of the feed source, in which the allowable pressure for the supplied system is exceeded.

- Water increases in volume when heated in a boiler or heat exchanger. The specific volume increase when heated from 0 to 100 °C is only 4%, so it is usually not the predominant factor when selecting the type size of the safety valve.

The selected safety valve must provide for the discharge of the calculated volume of water according to the most significant of the volume increase factors.

Selecting a safety valve

The diameter of the inlet pipe of the selected safety valve must be greater than or equal to the diameter of the pipe obtained as a result of the calculation.

In addition to the compliance of the pipe diameter with the calculated value, it is recommended to test the safety valve for the discharge of the calculated volume of water in the event of an emergency situation. At the same time, it should be taken into account that the greater the pressure difference between the pressure at which the safety valve opens and the pressure in the discharge line, the greater the volume of water that will come out through the valve.

question : comment : feedback

Online Equipment calculations

Online Equipment calculations

EXAMPLE

EXAMPLE