Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

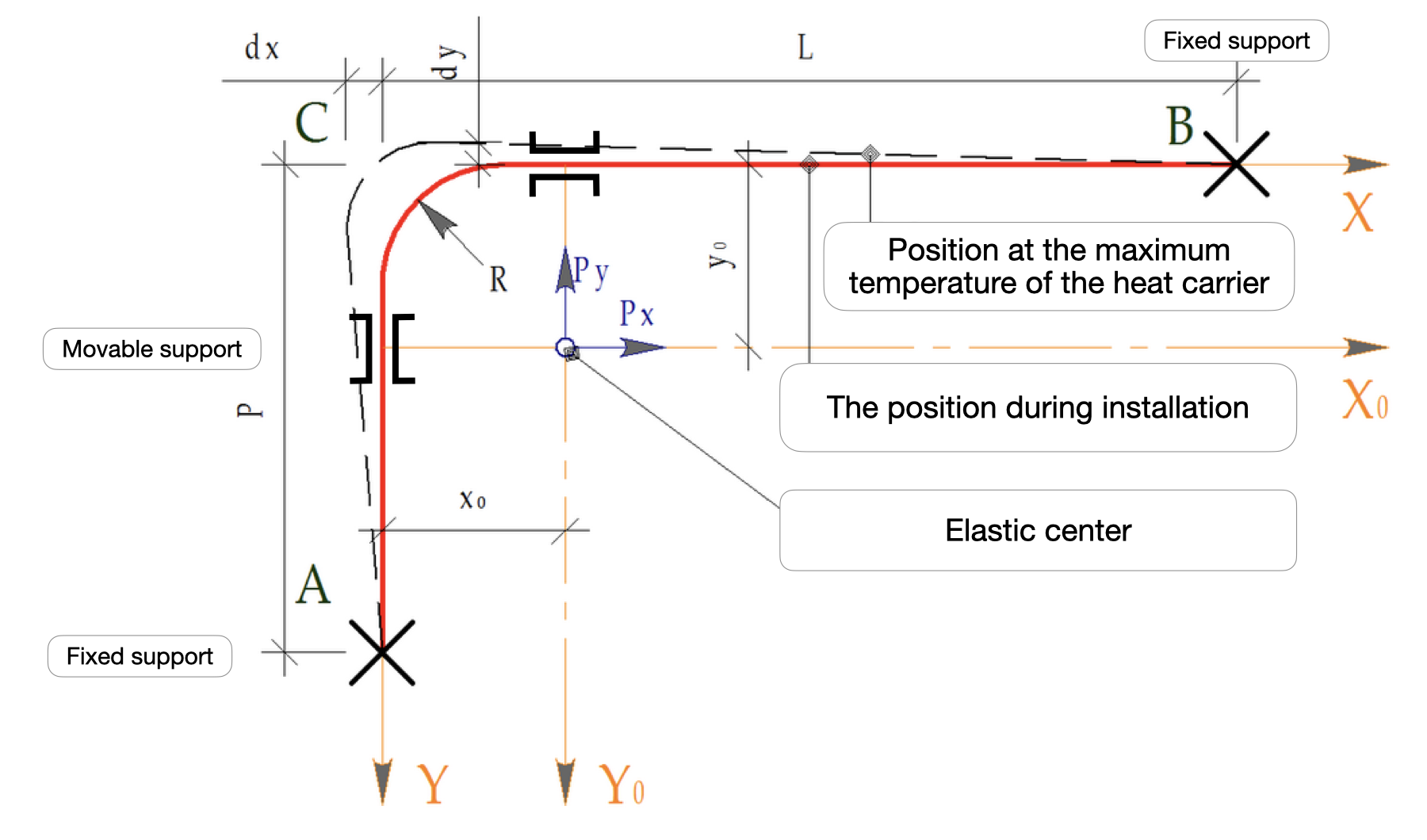

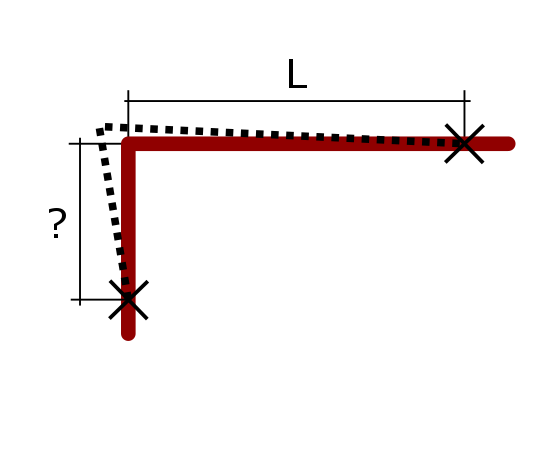

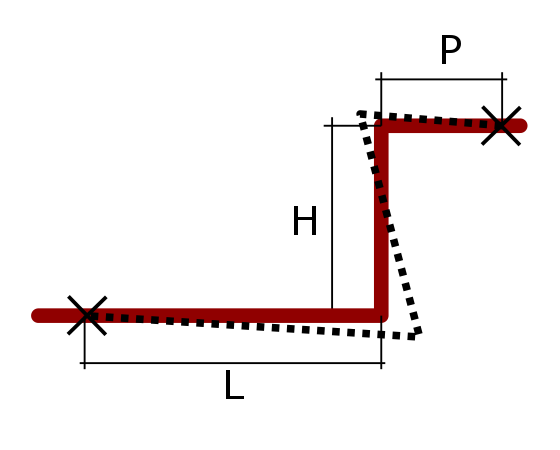

Calculation of the L-shaped pipe compensator

Calculation of the length of the short arm of the L-shaped compensator

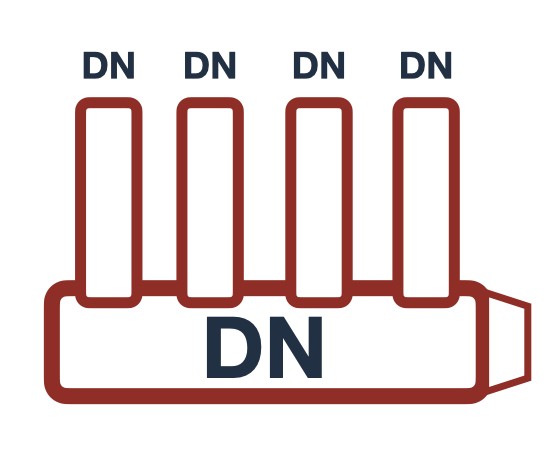

L-shaped compensators are called angles of turns of the pipeline, which are used to compensate for the thermal elongation of the pipes. The use of pipe rotation angles (self-compensation) is used for all methods of laying heat networks, regardless of pipeline diameters and hot-water parameters.

Recommendations for calculation

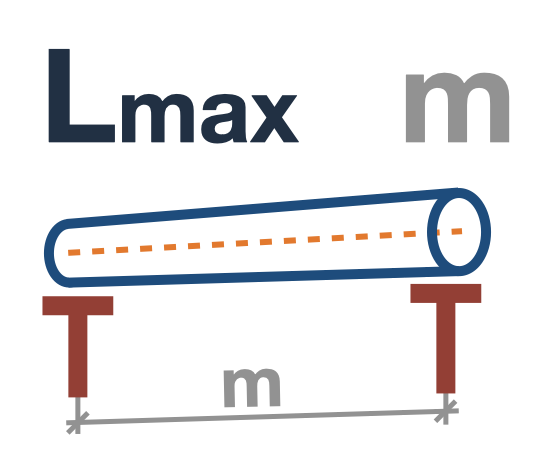

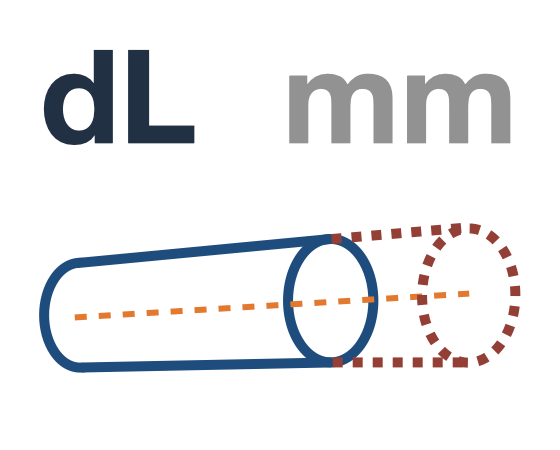

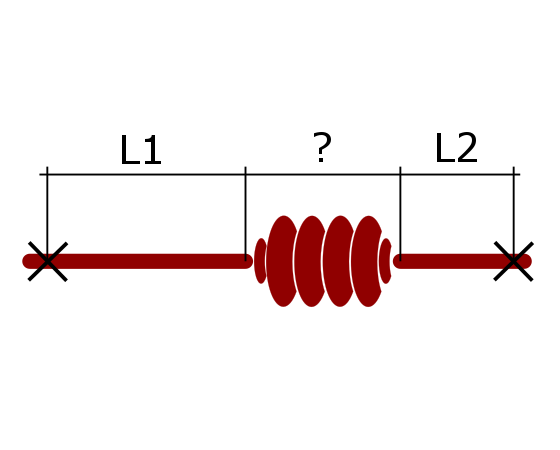

Calculation of the L-shaped pipe compensator consists in determining the length of the short arm, necessary to compensate for the thermal elongation of the long arm of the compensator, at which the maximum allowable bending stress will not be exceeded.

- It is recommended to set the maximum tension in the self-compensation areas to no more than 80 MPa.

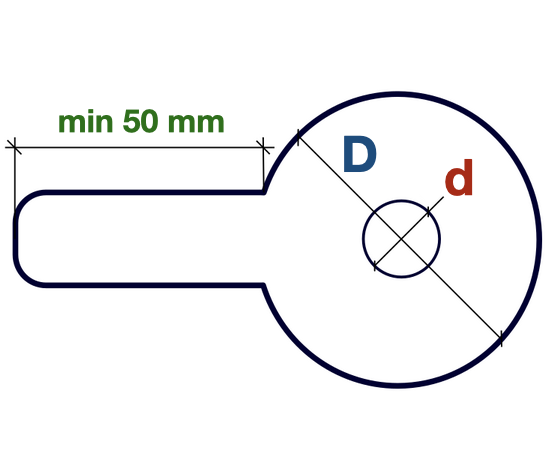

- The dimensions of the compensator obtained as a result of the calculation should be checked for lateral displacement of the pipeline. The pipeline should not move more than the gap between the outer surface of the insulating structure and the building structure.

- To compensate for the thermal elongation of pipes, pipeline bends with an angle of 90 to 130° are used.

The following restrictions are accepted in the calculation

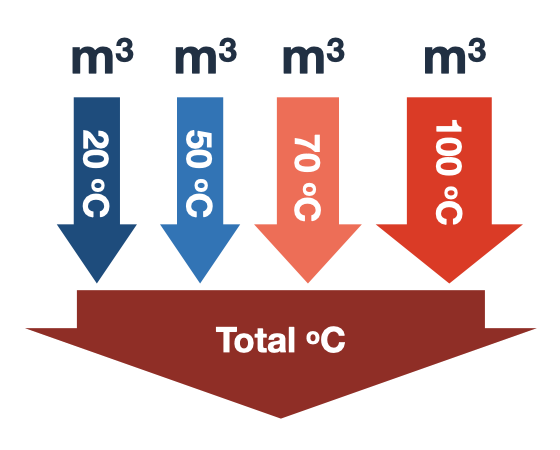

- The pipeline is filled with water or steam

- The pipeline is made of steel pipe

- The maximum temperature of the working environment does not exceed 200 °С

- The maximum pressure in the pipeline does not exceed 1.6 MPa (16 bar)

- The compensator is installed on a horizontal pipeline

- Fixed supports are considered absolutely rigid

- The pipeline does not feel wind pressure and other loads

- The resistance of the frictional forces of the movable supports during thermal elongation is not taken into account

- The knee is smooth with an angle of rotation 90°

Installation recommendations

- At the maximum temperature of the water, the angle of the compensator should not rest against the wall of the tray, therefore, the tray at the point of the pipeline turn is made of large sizes.

- Preliminary stretching of the self-compensation sections is provided for constructive reasons, if it is not possible to increase the length of the self-compensation section.

Online Calculations

Online Calculations

EXAMPLE

EXAMPLE