Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

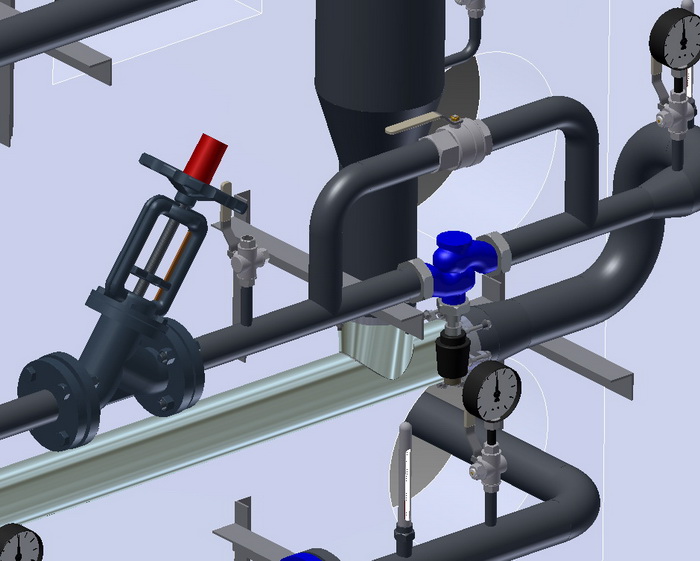

Installation of a direct-acting temperature regulator

Installation of a direct acting temperature regulator should be carried out in accordance with the installation instructions, and the following should also be taken into account:

- The mounting position should be selected on a horizontal pipeline with the thermostatic actuator downwards, unless otherwise stated in the installation instructions.

- Before the temperature regulator, it is recommended to have a straight section of pipeline of at least 5DN, and after it, of at least 10DN. Otherwise, the flow capacity may differ from the nominal values.

- The installation of the temperature regulator should exclude any bending, twisting, compression or stretching forces from the connected pipelines.

- Pressure gauges should be installed before and after the regulator, and a control thermometer should be installed at the temperature sensor location. It should be noted that tapping a thermometer into a pipeline DN50 and smaller without an expansion device is not allowed.

- A strainer should be installed before the regulator in the direction of water flow.

Sequence for packing a threaded connection

1. Take a flax fiber string with enough threads so that its twisted diameter is approximately equal to the depth of the thread. The length of the string should provide for 1.5-2 times more windings than the number of thread turns.

2. Starting approximately 50-70 mm from the beginning of the string, slightly twist it, place it in the first thread turn, and, holding it with your hand, tightly wind a long branch of the string clockwise, placing it in each thread turn.

3. When reaching the end of the thread, continue winding with a second layer, shifting the turns to the beginning of the thread. The length of the second layer winding should be approximately equal to 2/3 of the thread length.

4. Wind the remaining end of the string (50-70 mm) similarly clockwise, from the end of the thread to its beginning.

5. Apply a layer of sealant to the winding surface.

6. Tighten the connecting elements by hand. With correct packing, the assembled element should turn 1.5-2 full rotations.

7. Continue tightening the element with a wrench or a torque wrench. In case the assembled element needs to be in a specific position, complete tightening it in the necessary position of the element.

With proper packing, during tightening, the force should not exceed the tightening torque listed below:

| DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 |

|---|---|---|---|---|---|---|---|---|

| 70 Nm | 95 Nm | 120 Nm | 150 Nm | 190 Nm | 230 Nm | 280 Nm | 350 Nm | 400 Nm |

Tightening torques for flange connections

| DN | Nut/Bolt | Torque, Nm |

|---|---|---|

| 15 - 32 | М 10 | 15 - 30 |

| 40 - 65 | М 12 | 35 - 50 |

| 80 - 100 | М 16 | 75 - 100 |

| 125 - 150 | М 16 | 80 - 120 |

| 200 | М 20 | 150 - 200 |

| 250 - 400 | М 24 | 340 - 410 |

| 500 | М 27 | 340 - 410 |

question : comment : feedback

217

Catalog of

Catalog of temperature controllers

Danfoss

Danfoss

Danfoss

Danfoss

Danfoss

ARI Armaturen

ARI Armaturen

ARI Armaturen

ARI Armaturen

Termen

Termen

Samson

Samson

Samson

Samson

Samson

LDM

EN 1092-1

EN 1092-1