Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Servicing and repair of circulation pump

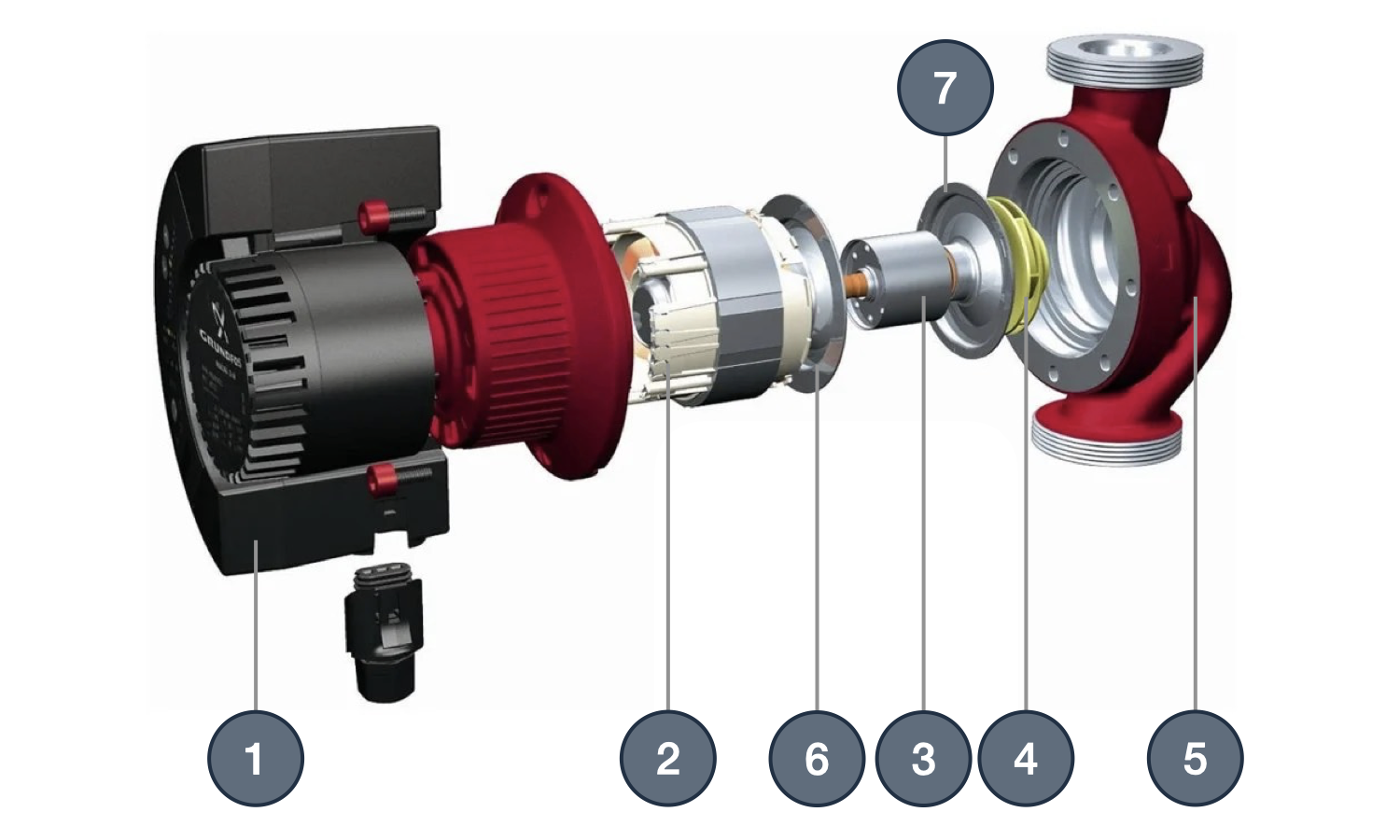

- 1 - Control unit

- 2 - Stator

- 3 - Rotor

- 4 - Impeller

- 5 - Pump housing

- 6 - Stator protection

- 7 - Protective cover

Modern pumps practically do not require maintenance, and their repair, like any imported equipment, is better carried out in service centers, so all recommendations are more related to preventing breakdowns, before the fact of stopping the circulating pump.

Operation

- The pump should not operate with zero delivery.

- Operating the pump without liquid is not allowed.

- The pump should operate within the permissible range of flow rates. The operation of the circulating pump with too low or high delivery can cause premature failure.

- During long downtimes, it is recommended to turn on the pump for 10-15 minutes with a periodicity of approximately once a month. Otherwise, oxidation and blocking of the shaft may occur.

- The water temperature in hot water supply systems equipped with wet rotor circulating pumps should not exceed 65°C. This restriction is introduced to prevent the precipitation of hardness salts.

Periodic maintenance

- Make sure there is no noise and vibration.

- Check the pump operation mode according to its head-flow characteristic.

- Check for excessive heating of the pump motor.

- Resume lubrication of the threaded part of the flange connections bolts.

- Visually check for grounding on the pump body.

- Check for leaks at the pump connections to the pipeline and, if necessary, tighten the connections and replace gaskets.

- Check the quality of the electrical cable connections in the terminal block and ensure that there is no moisture on it.

Possible malfunctions and methods for their elimination

The device of the wet rotor pump is based on a modular principle. The modules are equipped in various configurations depending on the size and required power. This facilitates the repair of circulating pumps and reduces it to replacing the module that has failed with a new one.

Attention! All work on repairing circulating pumps should be carried out after disconnecting the power and draining the section.

| Malfunction | Cause | Repair |

|---|---|---|

| The pump turns on, makes noise, but the shaft does not rotate | The shaft oxidized after a long downtime | If the pump is blocked, do not leave the motor powered to prevent damage to the winding. Drain the water and unscrew the screws that tighten the pump housing with the electric motor. Remove the electric motor with the impeller and rotor. Turn the impeller by hand. In low-power pumps, the shaft can be unlocked by turning it with a screwdriver for which a special notch is provided in the shaft end. |

| - - - | A foreign object blocked the impeller | Remove the electric motor (see above). Remove the foreign object. To prevent re-blocking, install a mesh filter in front of the pump. |

| - - - | Electrical power problems | Check the power supply voltage for compliance with the circulating pump passport data. Check the correctness of the connections in the terminal box and the presence of all phases. |

| The pump does not turn on and makes no sound | The power supply voltage is absent or does not correspond to the passport data | Check and correct the problem. |

| - - - | The fuse is damaged (if the pump is equipped with one) | Replace the faulty fuse. If replacing the fuse does not solve the problem, the motor winding may be burned out. |

| The pump turns on but stops after a while | Lime deposits have formed between the rotor and the stator housing | Remove the motor block and clean the stator housing from scale. |

| Sharp noise when turning on | Air in the 'dry run' flow part | Release the air and install an automatic air vent at the top of the pump assembly to prevent further air buildup. |

| - - - | Cavitation (accompanied by vibration) | Increase the pressure in the suction pipe to a value exceeding the cavitation margin. |

| Pump vibration | Worn bearing (accompanied by noise) | Replace the worn bearing. |

| Delivery and head below rated values | Reverse rotation of the impeller | Typical for incorrectly connected three-phase pumps. |

| - - - | The circulatory ring has too high hydraulic resistance | Clean the filter and check the diameter calculation of the regulating fittings and pipes. |

| External motor protection trips after starting | Problems with the electrical system | 1. Check the presence of phases in the terminal box. 2. Check for possible open or dirty fuse contacts. 3. Check the phase resistance to ground. |

question : comment : feedback

580

Catalog of

Catalog of circulation pumps

DAB

DAB

DAB

DAB

Wilo

Wilo

Wilo

Wilo

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

Calpeda

Calpeda

Calpeda

Calpeda

Calpeda

Grundfos

Wilo

Wilo

Wilo

Wilo

Wilo

Calpeda

Calpeda

Grundfos

Grundfos

Grundfos

Grundfos

Grundfos

DAB

DAB

Smedegaard

Smedegaard

Smedegaard

Lowara

Lowara

Lowara

Lowara

Lowara

IMP Pumps

Tutorial Grundfos

Tutorial Grundfos